Imagine a fabric that has the lustrous shine of silk on the outside but the soft, breathable comfort of cotton on the inside. This is the magic of Mashru. Now, picture a fabric so intricately woven that it looks like a rich brocade, carrying patterns inspired by ancient caves and Persian art. That is the splendor of Himroo.

These two textiles, born in different parts of India, share a common thread of genius craftsmanship and a fascinating history. Mashru, from the vibrant land of Gujarat, was created out of a religious need, while Himroo, from the historic city of Aurangabad, was born to serve royalty. Together, they represent the incredible diversity of India's weaving heritage.

In this guide, we will unravel the stories of Mashru and Himroo. We'll explore their unique origins, understand the complex techniques used to create them, and see how these regal fabrics are navigating the modern world.

Mashru: The Fabric of Permission

The story of Mashru is a brilliant example of innovation driven by faith. The name itself gives a clue to its origin. "Mashru" means "permitted" in Arabic, and its Sanskrit variation, "Misru," means "mixed."

A Clever Solution to a Religious Rule

The craft of weaving Mashru is said to have originated in West Asia around the 19th century and was perfected in places like Patan and Mandvi in Gujarat. Its creation was a direct response to a religious belief within some Muslim communities that prohibited men from wearing pure silk against their skin.

However, the allure of silk's luxurious sheen was undeniable. To solve this, weavers developed a unique fabric. They created a textile where the outer surface that everyone sees is made of shimmering silk threads, but the inner lining that touches the skin is made of soft, comfortable cotton. This clever blend made the fabric "permitted" or lawful to wear, giving men the royal look of silk without breaking religious customs.

How is Mashru Made?

The weaving process of Mashru is a masterclass in textile engineering. It is a satin weave, which is what gives it that characteristic smooth and glossy surface.

- Setting the Loom: The process begins by setting up the warp (the vertical threads) with silk yarn. A typical loom is set up with about 63 yards of silk.

- Weaving the Weft: The weft (the horizontal threads) is woven using cotton yarn. The unique structure involves floating the silk warp threads on the surface while the cotton weft remains at the back. This means that for every few silk threads on top, there is a cotton thread underneath, creating two distinct layers in one fabric.

- Finishing the Fabric: Once woven, the fabric is washed and then rigorously beaten with wooden bars while it is still wet. This helps to settle the threads. A paste of wheat flour is often applied to the threads to maintain their consistency and add to the final sheen.

- Dyeing: Finally, the fabric is dyed in vibrant, bold colors, which makes the silk surface pop with a brilliant lustre. The result is a fabric that is firm, durable, and surprisingly comfortable, making it suitable for both grand occasions and utility wear.

Himroo: A Royal Weave from Aurangabad

While Mashru was born from permission, Himroo was born from royal ambition. This luxurious fabric is a traditional specialty of Aurangabad in Maharashtra and is a living symbol of the region's rich weaving history.

From Tughlaq's Court to Aurangabad's Looms

The origins of Himroo date back to the reign of Mohammad Tughlaq in the 14th century. When Tughlaq decided to shift his capital from Delhi to Daulatabad (near Aurangabad), many skilled artisans and weavers moved with him. Though he later moved the capital back, many of these craftsmen stayed behind, planting the seeds for Aurangabad's textile industry.

Himroo weaving flourished under royal patronage. It was used to create shawls, stoles, and other grand items for the royal households. The designs were heavily influenced by the rich art and architecture of the time, including the intricate patterns found in the nearby Ajanta and Ellora caves.

How is Himroo Made?

Himroo is often described as a "second-class brocade" because it mimics the look of the more expensive silk-and-gold brocades but is made with more accessible materials.

- The Base: The base of Himroo is spun with cotton or wool. This forms the main structure of the fabric.

- The Design: The intricate patterns are woven into the fabric using silk threads. Like Mashru, it uses a mix of cotton and silk, but the technique is different. Himroo uses a discontinuous weft, meaning small spools of silk thread are used to create motifs on the cotton base.

- Inspiration and Motifs: The designs are the soul of Himroo. Weavers took inspiration from everything around them:

- Nature: Local fruits, flowers (like the lotus), birds, and animals were common.

- Geometry: Intricate geometric patterns were popular.

- Persian Art: The designs were also inspired by the rich kimkhwab fabrics of Persia, which used real gold and silver threads.

- Architecture: The majestic arches and jaalis of monuments like the Taj Mahal were woven into the fabric.

The Shared Beauty: Design and Feel

Though their stories are different, Mashru and Himroo share some similarities. Both fabrics use a blend of cotton and silk to create a textile that is both beautiful and practical. The silk provides a regal, glossy finish, while the cotton ensures breathability and comfort.

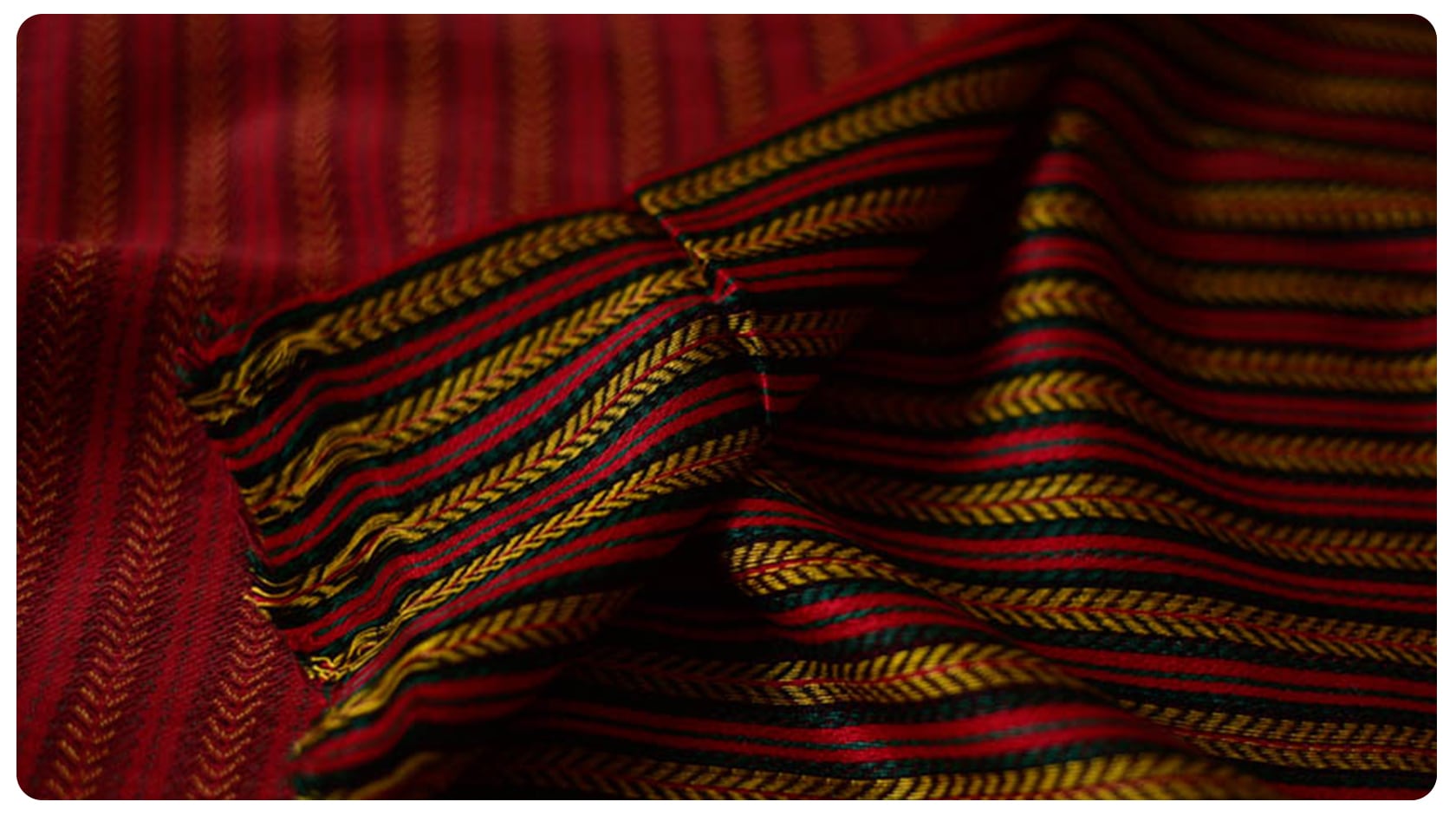

Mashru Designs: Known for its vibrant, striped, or dotted patterns. The bright colors and glossy finish make it a statement fabric.

Himroo Designs: Known for its all-over woven patterns that tell a story. The motifs are dense and create a texture that looks incredibly rich and detailed.

Challenges and the Fight for Survival

Both Mashru and Himroo are facing a battle against time. The traditional, handwoven versions of these fabrics are becoming increasingly rare.

1. The Rise of Power Looms: Modern power looms can produce similar-looking fabrics much faster and cheaper. This has made it difficult for handloom weavers to compete.

2. Cheaper Materials: To cut costs, many producers now use rayon instead of silk and cheaper chemical dyes instead of natural ones. This compromises the quality and authenticity of the final product.

3. Declining Number of Artisans: Weaving these fabrics is a skill passed down through generations. With low profits and hard labor, the younger generation is often not interested in continuing the family tradition.

While the art of Mashru is nearly extinct in its most authentic form, Himroo survives as one of the last relics of Aurangabad's regal past. Efforts are being made by designers and government bodies to support the remaining weavers and create a market for these handmade treasures.

Conclusion

Mashru and Himroo are more than just fabrics; they are chapters from India's history book. Mashru tells a tale of creative problem-solving and cultural adaptation, while Himroo sings a song of royal grandeur and artistic excellence.

They remind us that the most beautiful things are often born from a blend of different worlds—silk and cotton, faith and fashion, tradition and innovation. By appreciating and supporting these handwoven textiles, we help keep the looms running and ensure that the stories woven into these threads are not forgotten. The next time you see a piece of Mashru or Himroo, you'll know you are looking at a true woven wonder.