In an age of digital prints and fast fashion, there is something deeply satisfying about wearing a fabric that tells a story. A story carved into wood, dipped in color, and stamped by hand, thousands of times. This is the art of Hand Block Printing.

If you have ever admired a cotton kurta with delicate floral motifs or a bedsheet with intricate geometric patterns, you have likely witnessed the magic of this craft. While it is practiced in various forms across the world, Rajasthan in India remains its beating heart.

In this guide, we will travel through the history of block printing, uncover the secrets of how it is made, and see why this manual art form is still relevant in a machine-dominated world.

A Journey Across Continents: From China to Rajasthan

Hand block printing is not new. In fact, it is ancient. Historians believe the technique originated in China as early as the 3rd Century. Evidence of block-printed fabrics has also been found in ancient Egypt and other parts of Asia dating back to the 4th Century.

However, the story truly comes alive in India. Over 2,000 years ago, communities like the Chippas and Khatris brought their skills to the desert lands of Rajasthan. They settled in villages that are now famous worldwide for their distinct styles: Bagru, Sanganer, and Barmer.

These villages transformed Rajasthan into a global hub for block printing. What started as a local craft for turbans and lungis has now become a major economic engine, exporting textiles to every corner of the globe.

The Heart of the Craft: Design and Blocks

The soul of block printing lies in the block itself. Without these masterfully carved tools, there is no print.

Types of Blocks

There are typically two types of blocks used by artisans:

- Wooden Blocks: These are the most common. Artisans carve intricate motifs into timber using steel chisels. These blocks often have a wooden handle and small holes to let air pass through, preventing the dye from blobbing.

- Rekh: The outlining block that defines the shape

- Gadh: The filling block that adds color inside the outline. To make them durable, these blocks are soaked in oil for 10-15 days before use. Even then, a wooden block usually lasts for about 600-800 meters of printing before it wears out.

- Metallic Blocks: For certain designs, artisans use metal sheets. These sheets are beaten into thin strips and hammered into a wooden base to create the outline. While expensive and harder to make, metallic blocks last much longer than wooden ones and provide very sharp, crisp lines.

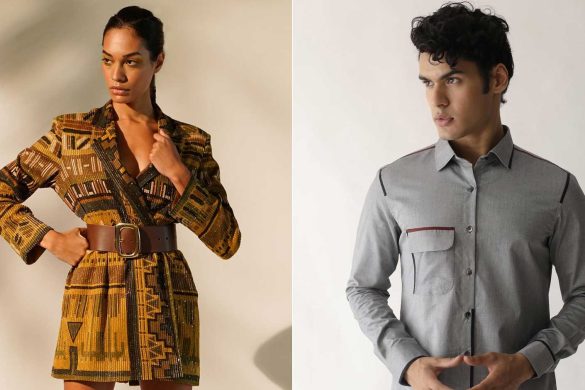

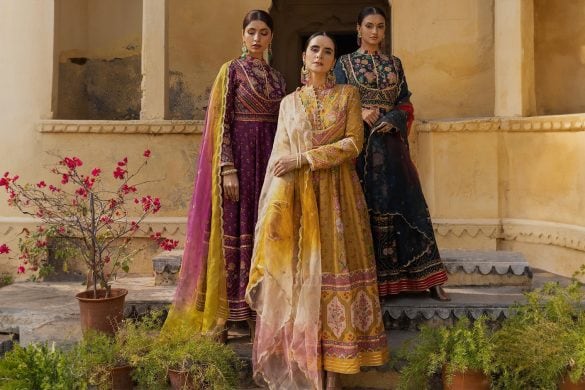

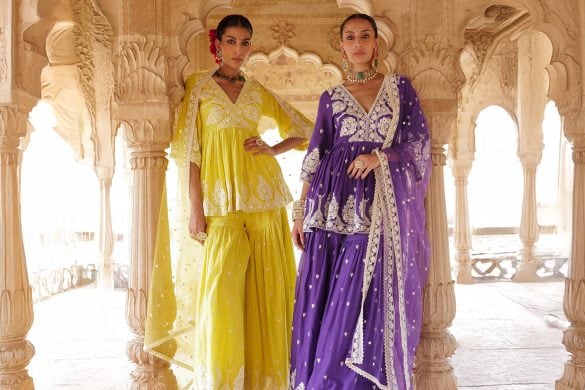

Regional Styles and Colors

Different villages in Rajasthan are known for different looks:

- Bagru: Famous for natural dyes and earthy tones like indigo blue, madder red, and black. The motifs are often floral and intricate.

- Sanganer: Known for finer, more delicate floral patterns, typically on a white background with muted colors.

- Barmer: Inspired by Sindh (Pakistan), this style features bold geometric patterns, vibrant red chilies, and blue or black outlines.

- Ajrakh: A complex geometric style often seen in deep reds and blues, historically worn by the pastoral communities.

The Process: How the Magic Happens

Hand block printing is a test of patience and precision. A single design might require 2 to 4 different colors. For every color, a separate block is needed. If a design has four colors, the artisan must stamp the fabric four times in the exact same spot without shaking their hand.

Here are the main techniques used:

1. Direct Block Printing

This is the most straightforward method. The fabric (usually cotton or silk) is first bleached and dyed a base color. Then, the artisan dips the carved block into the dye tray and presses it onto the cloth. They start with the outline (Rekh) and then fill it in with the color block (Gadh). Bagru prints are a classic example of this technique.

2. Resist Printing

This is a bit like magic. Instead of dye, the artisan prints with a paste made of resin and clay (called dabu). This paste covers specific parts of the fabric. The cloth is then dipped in a dye bath. The parts covered by the paste "resist" the dye and remain the original color. Once washed, the clay comes off, revealing the design. Ajrakh prints often use this technique.

3. Discharge Printing

In this method, the fabric is dyed a solid color first. Then, a chemical is printed onto the fabric using blocks. This chemical removes (discharges) the dye from those specific areas, leaving a pattern behind. These areas can then be re-colored if needed.

Once the printing is done, artisans often brush fine sawdust over the wet dye. This locks the color in and prevents it from smudging while it dries.

Challenges in a Modern World

Despite its beauty, hand block printing faces significant hurdles today.

1. The "Fast Fashion" Threat

Modern screen printing and digital printing can mimic the look of block prints at a fraction of the cost and time. A machine can print hundreds of meters in an hour, while an artisan might take a whole day to print just a few meters. This makes genuine hand-blocked fabric more expensive.

2. Artisan Shortage

It is hard, labor-intensive work. Standing for hours, aligning blocks with millimeter precision, and working with dyes takes a toll. Many younger people from artisan families are choosing easier, better-paying office jobs, leading to a shortage of skilled labor.

3. Authenticity Issues

Many fabrics sold as "block print" today are actually screen-printed fakes. It can be hard for customers to tell the difference, which hurts the livelihood of genuine craftsmen.

Conclusion: Why It Still Matters

So, why should we care about hand block printing? Because it is perfectly imperfect.

When you look closely at a hand-blocked shirt, you might see a tiny overlap of color or a slight variation in the shade. These aren't defects; they are the "human mark." They prove that a person, not a machine, made your clothes.

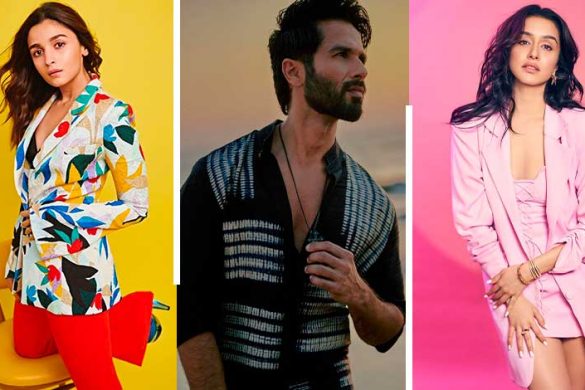

Fortunately, awareness is growing. Designers like Anita Dongre and Abraham & Thakore are championing this art, bringing it to global runways. The demand for sustainable, eco-friendly, and handmade fashion is giving Rajasthan's artisans a new lease on life.

By choosing authentic block-printed fabrics, you aren't just buying a piece of cloth. You are keeping a 2,000-year-old tradition alive, ensuring that the rhythmic thump-thump-thump of the wooden block continues to echo through the villages of Rajasthan.